Kolev Roll Forming Lines For Sale

Roll Forming Lines | Systems | Roll Tooling15″ Soffit 4 Panels Roll Forming Line for Sale

Made in Canada by KOLEV Engineering Inc.

NextGen Rollforming®

Ready to ship from Mississauga, Ontario.

Call: 905-696-0339

Email: sales@kolev.com

Roll Forming Line Description

This 15″ Soffit 4 panels KOLEV Roll Forming line is available for sale now. The rollforming line produces high-quality aluminum soffit panels with or without ventilation holes. A 6000 lb uncoiler with hydraulic expansion and laser loop controls feeds the material (aluminum 0.012″- 0.013.5″) to a roll forming machine with 14 passes. The rollforming machine has a 120 ft/min speed and includes a manual adjustable entry guide and encoder fixture. Pass 13 of the roll forming machine is the ventilation forming station equipped with Duff Norton actuators and Lansing Rolls. The 15″ Soffit 4 panels produced by the rollformer are post cut by HHSS hydraulic cut-off system. This Soffit Panel Roll Forming Line includes a 20 ft exit gravity conveyor and electrical controls. KOLEV Engineering provides on-site installation and commissioning of this Roll Forming Line and export packaging and documentation for US customers. See more details and specs below and inquire by contacting KOLEV Engineering Sales at 905-696-0339.

FOR SALE

KOLEV Roll Forming Line

15″ Soffit 4 Panels

Condition: Brand New

Location: Mississauga ON, Canada

Price: Inquire About Pricing at 905-696-0339

Availability: In Stock

KOLEV Soffit Panel Roll Forming Line

Configuration

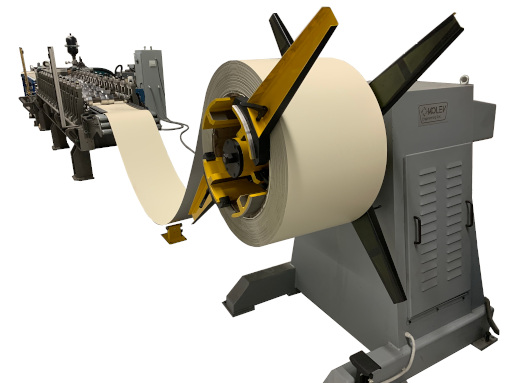

The Uncoiler of the 15″ Quad Vent/Non-Vent Aluminum Soffit Panel Roll Forming Line

- 6000 Lb,

- single mandrel,

- hydraulic expansion,

- full-time drive,

- laser loop control

Uncoiler 6000 lb, Single Mandrel, 24” face

- Max. Weight of the coil: 3000 kg (6000Lb)

- Max. Coil OD: Ф1400mm (55in)

- Range of the ID of the coil: Ф465 (470) (18.5in)- Ф520mm (20.5in)

- Max. Coil Width 500mm (19.5in), at max. Mandrel width: 600 mm (23.63”)

- Speed of up to 45m / min (135fpm)

- Height from the floor to the axis of rotation of the mandrel: 1100 mm (43.3”)

- Mandrel:

– opening and closing of the jaws – by means of a hydraulic cylinder, a rotary distributor DEUBLIN and a built-in hydro-station (0.5 kV AC motor),

– Coil keepers – 8 pcs adjustable (4 + 4),

– Mandrel drive via a two-row circuit of 3.5 kW Siemens gear motor, with power supply parameters, AC 3PH / 575V / 60Hz, as well as a fan with independent rotation and a negative electric brake 10Nm, mounted on the shaft of an electric motor. - Electrical equipment:

– Electrical cabinet Rittal or Himel (fixed on the body of the machine laterally as shown in the diagram),

– Allen Bradley inverter,

– Removable panel connected with a flexible cable (4 m long). There are only buttons for rotating Forward, Back, and Av. Stop on the console,

– Sensors for automatic control of the development of the coil “ear-loop.”

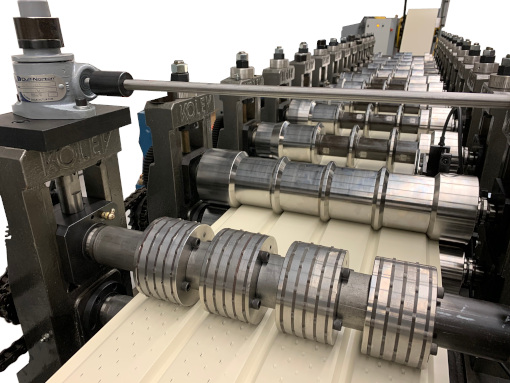

Roll Former – 14 Passes

- Heavy-duty base for 14 passes, welded structure I beam with machined surface

- Entry guide – manual adjustment on precision linear guides

- Shaft Diameter – 1.5” x 3/8 keyway

- 2 gear reducers, Cone drive

- Chain drive all bottom shafts

- Bottom to top shafts drive – gears to designated passes

- Horizontal distance – 12 3/4”

- Vertical Distance – 4.5” – 6.5”

- Roll tooling space – 20”

- Encoder fixture

- Working speed 120fpm

- Drive: 10HP AC motor, 1800 rpm, 575V, 3ph, VFD drive, and control panel for the roll former, plug and play

- Lansing station for ventilation holes Pass #14

The Roll Former with 14 passes of the Soffit Line

The Hydraulic High-Speed Shear of the Soffit Panel Roll Forming Line

- precision linear guides,

- 4 ½” HHSS cylinder,

- 8.5 ton to 12-ton shear,

- one set shear blades, D2, hardened, grind and EDM profiled,

- shear acceleration – by air cylinder.

Hydraulic High-Speed Shear Open Loop HHSS

Hydraulic power pack

L45– 15HP, Hydraulic power unit and components consisting of the items below for Flying HHSS Cut-off Press (x1) -45 gal. nom.

- L-style reservoir c/w large breather, level temp. switch, level temp. indicator,

1x 2” CD 61 return port, 1 x 3/4” NPT drain connection, - 15 HP.,1750 rpm 460 VAC./60Hz./3ph.,C-face Premium efficiency electric motor

- Parker, 7.5 GPM, variable displacement, pressure compensated piston pump. (set 2800 psi.),

- 24 VDC. solenoid ventable relief valve set at 3000 psi. max

- 1 HP. 460 VAC./60/3 1750 rpm. TEFC. motor for 9.5 GPM cooling & filtration loop pump,

- Extra large Air-Oil heat exchanger c/w 100°F temperature switch to activate motor fan start relay(s).